|

THE EVOLUTION OF LS ENGINE TECHNOLOGY

1997 General Motors debuted it's Gereration III small block, the LS1, in the C5 Corvette. It had 345 h.p. and 350 f.p.t. in an aluminum block 346 c.i.d. / 5.7L engine. 2001 The Corvette C5 Z06's LS6 came with higher lift cam and a higher compresssion ration to boost output to 385 h.p., and 385 f.p.t. In 2002 output was further increased to 405 hp and 400 f.p.t. 2005 General Motors introduced the Generation IV small block, the LS2 in the new C6 Corvette. It was more powerful, quieter, required less fuel, and required less oil than the LS6. It also had higher compression and a higher red line to create a broader power band. The displacement was now a 364 c.i.d. / 6.0L engine with 400 h.p., and 425 f.p.t. 2006 The Corvette Z06 now had an LS7; a 427 c.i.d. / 7.0L small block derived from the Katech 427 in the C5-R Corvette. It's output was 505 h.p., and 525 f.p.t. The car had a 0-60 time of 3.7 seconds. 2007 The C6.5 Generation Corvette has a newer LS power plant. The LS3, a 376 c.i.d. / 6.2L engine that will produce 436 h.p. and 450 f.p.t. The 2007 Z51 shows 1/4 tests speeds comparable to the 2002 Z06's 12.4 @ 117 m.p.h. 2008 A supercharged LS3 designated LS9 will be in the Corvette ZR1 (previously known as "Blue Devil" or Z07). It will have > 650 h.p. Stay tuned. New, Supercharged LS9 V-8 is the Heart of the ZR1

DETROIT - Chevrolet officially announced the 2009 Corvette ZR1 - an American supercar that brings the technology and engineering refinement of carbon-fiber, ceramics and electronics together in a distinctive design.

"Chevrolet's goal with the new ZR1 is to show what an American supercar can deliver, at a price that trumps exotics that cost two, three or four times as much - and does so with exceptional driveability," said Ed Peper, Chevrolet general manager.

The ZR1's basic stats:

* All-new LS9 supercharged 6.2L V-8 targeted at producing at least 100 horsepower per liter, or 620 horsepower (462 kW), and approximately 595 lb.-ft. of torque (823 Nm)

* Six-speed, close-ratio, race-hardened manual transmission

* New, high-capacity dual-disc clutch

* Higher-capacity and specific-diameter axle half-shafts; enhanced torque tube

* Specific suspension tuning provides more than 1g cornering grip

* Twenty-spoke 19-inch front and 20-inch rear wheels

* Michelin Pilot Sport 2 tires - P285/30ZR19 in front and P335/25ZR20 in the rear - developed specifically for the ZR1

* Standard carbon-ceramic, drilled disc brake rotors - 15.5-inch-diameter (394-mm) in the front and 15-inch-diameter (380-mm) in the rear

* Larger brake calipers with substantially increased pad area

* Standard Magnetic Selective Ride Control with track-level suspension

* Wider, carbon-fiber front fenders with ZR1-specific dual vents

* Carbon-fiber hood with a raised, polycarbonate window - offering a view of the intercooler below it

* Carbon-fiber roof panel, roof bow, front fascia splitter and rocker moldings with clear-coated, exposed carbon-fiber weave

* ZR1-specific full-width rear spoiler with raised outboard sections

* Specific gauge cluster with boost gauge (also displayed on the head-up display) and 220-mph (370 km/h) speedometer readout

* Only two options: chrome wheels and a "luxury" package

* Curb weight of approximately 3,350 pounds (1,519 kg)

The specialized components of the new ZR1 work harmoniously to deliver the most powerful and fastest automobile ever produced by General Motors. Performance estimates will be announced closer to vehicle's summer 2008 launch.

"Preliminary testing shows the ZR1 builds on the highly respected Corvette Z06 in every performance category, from acceleration and braking, to cornering grip and top speed," said Peper. "It all boils down to the power-to-weight ratio and the ZR1's is exceptional - better than the Porsche 911 GT2, the Ferrari 599 and even the Lamborghini LP640. In fact, the ZR1 is expected to be the first production Corvette to achieve a top speed of at least 200 mph."

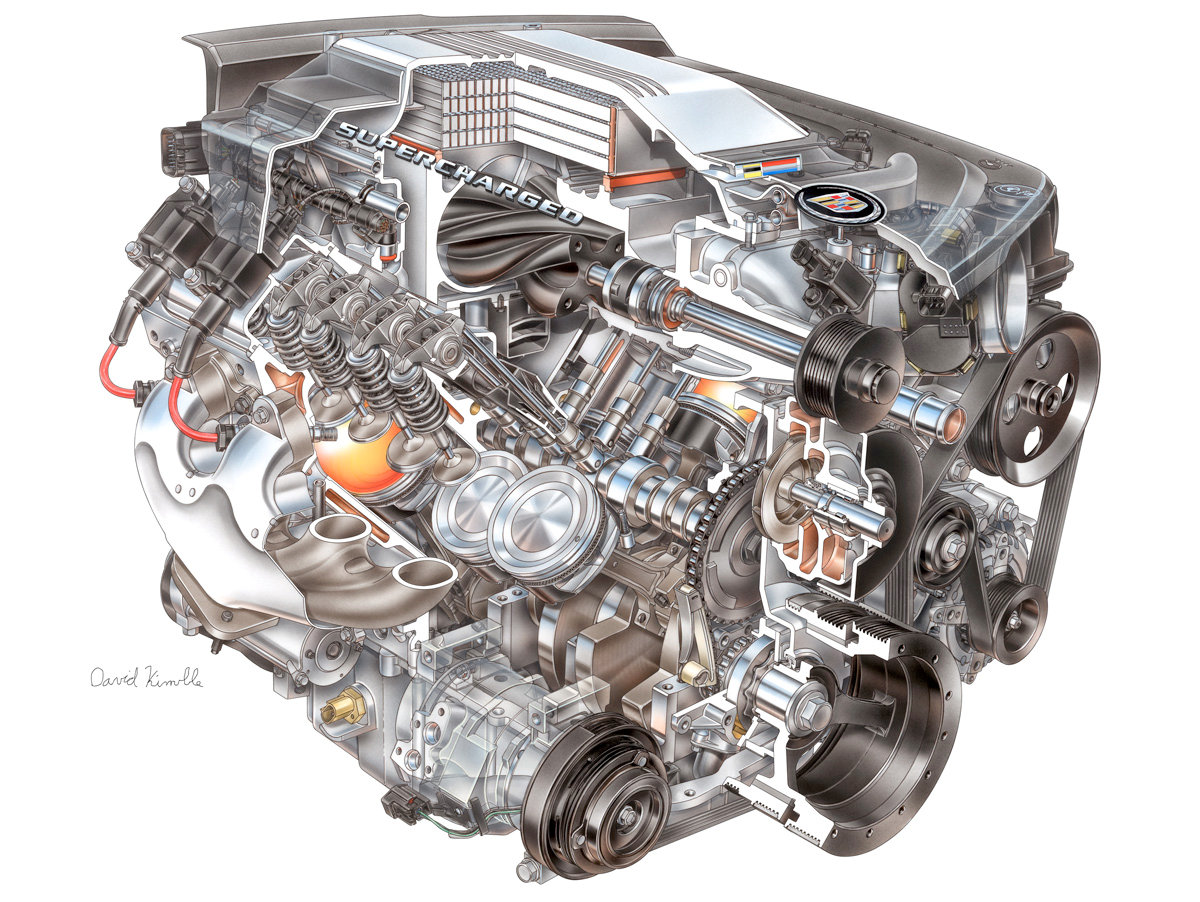

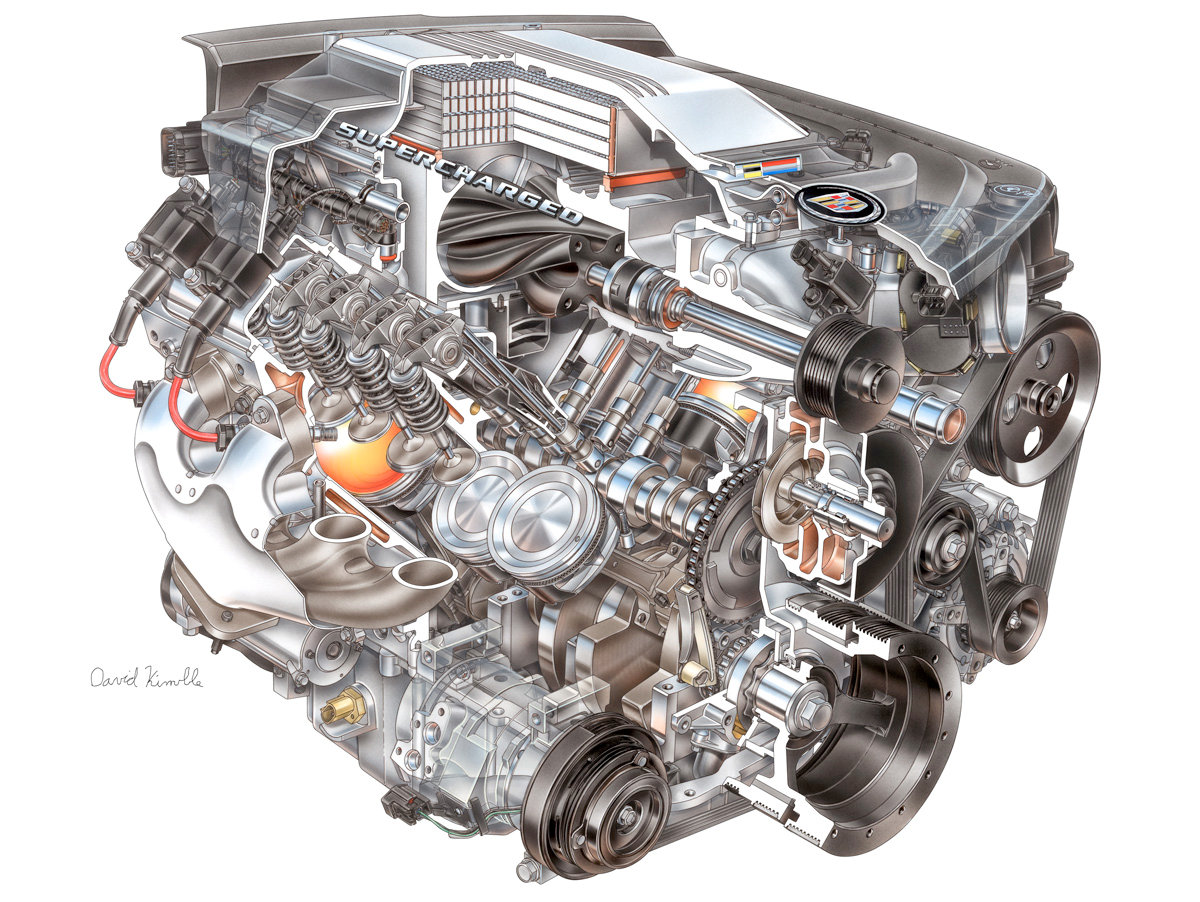

Supercharged LS9 engine

The new LS9 6.2L small-block engine is the power plant the supports the ZR1's performance capability. The enabler of the LS9's performance and refinement is a large, positive-displacement Roots-type supercharger with a new, four-lobe rotor design. It is augmented with an integrated charge cooling system that reduces inlet air temperature for maximum performance.

A sixth-generation supercharger developed by Eaton helps the LS9 make big power and torque at lower rpm and carries it in a wide arc to 6,600 rpm, as it pushes enough air to help the engine maintain power through the upper levels of the rpm band - the area where supercharged performance tends to diminish. Heavy-duty and lightweight reciprocating components enable the engine's confident high-rpm performance.

The LS9 is hand-assembled at GM's Performance Build Center, in Wixom, Mich., and incorporates specialty processes typically seen in racing engines to produce a highly refined and precise product. For example, cast iron cylinder liners are inserted in the aluminum block and are finish-bored and honed with a deck plate installed. The deck plate simulates the pressure and minute dimensional variances applied to the block when the cylinder heads are installed, ensuring a higher degree of accuracy that promotes maximum cylinder head sealing, piston ring fit and overall engine performance.

Transmission and axle

The LS9 engine is backed by a new, stronger six-speed manual transmission and a twin-disc clutch that provide exceptional clamping power, while maintaining an easy clutch effort. ZR1-specific gearing in the transmission provides a steep first-gear ratio that helps launch the car, and top speed is achieved in sixth gear - a change from the fifth-gear top-speed run-outs in the manual-transmission Corvette and Corvette Z06.

As the term implies, the twin-disc clutch system employs a pair of discs, which spreads out the engine's torque load over a wider area. This enables tremendous clamping power when the clutch is engaged, while also helping to dissipate heat better and extend the life of the clutch.

The twin-disc clutch system also contributes to the ZR1's exceptional driving quality, with smooth and easy shifting. The twin-disc system's design enables a 25-percent reduction in inertia, thanks to smaller, 260-mm plates, corresponding to a pedal effort that is similar to the Corvette Z06's 290-mm single-disc system.

The rear axle also is stronger in the ZR1 and features asymmetrical axle-shaft diameters that were developed after careful testing to provide optimal torque management. The axles are also mounted on a more horizontal plane that correlates with the wider width of the rear wheels and tires.

Ride and handling

The ZR1 is built on the same aluminum-intensive chassis as the Corvette Z06 and features similar independent SLA front and rear suspensions, with aluminum upper and lower control arms. Where the ZR1 differs is the suspension tuning, which was optimized for the car's steamroller-wide front and rear tires.

Magnetic Selective Ride Control is standard and tuned specifically for the ZR1. The system's ability to deliver a compliant ride with nearly instantaneous damping adjustments enabled engineers to develop a surprisingly supple ride quality in a supercar that still delivers cornering grip of more than 1g.

From a high-performance perspective, Magnetic Selective Ride Control helps the rear axle remain planted during launch for smooth, hop-free acceleration. It also helps suppress axle movement when cornering on broken or uneven pavement.

Brakes, wheels and tires

Commensurate with the ZR1's engine output is the braking system, which is headlined by carbon-ceramic brake rotors. Found ing system, which is headlined by carbon-ceramic brake rotors. Found on only a few exotics and more expensive supercars, carbon-ceramic brake rotors are made of a carbon-fiber-reinforced ceramic silicon carbide material . Their advantage comes in low mass and resistance to wear and heat. In fact, the rotors should never show any corrosion or require replacement for the life of the vehicle, when used in normal driving.

The vented and cross-drilled rotors on the ZR1 measure 15.5 inches (394 mm) in diameter in the front and 15 inches (380 mm) in diameter in the rear - making them among the largest carbon-ceramic rotors available on any production vehicle.

Clamping down on the high-tech rotors are six-piston front calipers and four-piston rear calipers, each painted a ZR1-exclusive blue. The front pads are equivalent in size to the largest on any production car with a single-pad design - double that of the Corvette Z06's 70-sq.-cm. front pads.

The brakes are visible through the ZR1's exclusive wheels: 20-spoke alloy rims that measure 19 inches in diameter in the front and 20 inches in the rear. They come standard with a bright, Sterling Silver paint finish and chrome versions are optional. The wheels are wrapped in Michelin Pilot Sport 2 tires developed specifically for the ZR1, measuring P285/30ZR19 in front and P335/25ZR20 in the rear.

Exclusive exterior

The ZR1 is instantly recognizable, with perhaps the most identifiable feature a raised, all-carbon-fiber hood that incorporates a clear, polycarbonate window. The window provides a view of the top of the engine's intercooler, with the legend "LS9 SUPERCHARGED" embossed on the left and right sides, and an engine cover with the Corvette crossed flags logo debossed at the front.

The underside of the hood has an exposed carbon-fiber-weave. Exposed carbon-fiber is used on the roof, roof bow, rocker molding and front splitter. These exterior components are protected by a specially developed glossy, UV-resistant clear coat that resists yellowing and wear.

Widened, carbon-fiber front fenders with specific, dual lower vents, and a full-width, body-color rear spoiler incorporating the center high-mounted stop lamp, are also unique to the ZR1. All of the exterior features of the car were developed to enhance high-speed stability and driver control.

Interior details

The ZR1's interior builds on the brand's dual-cockpit heritage, with high-quality materials, craftsmanship and functionality that support the premium-quality experience promised by the car's performance. The ZR1's cabin differs from the Corvette and Corvette Z06 with the following:

* ZR1-logo sill plates

* ZR1-logo headrest embroidery

* Specific gauge cluster with "ZR1" logo on the tachometer and a 220-mph (370 km/h) readout on the speedometer

* Boost gauge added to the instrument cluster and Head-Up Display

The "base" ZR1 (RPO 1LZ) comes with accoutrements based on the Z06, including lightweight seats and lightweight content. The uplevel interior package includes unique, power-adjustable and leather-trimmed sport seats (embroidered with the ZR1 logo); custom, leather-wrapped interior available in four colors; navigation system, Bluetooth connectivity and more.

By the numbers

In addition to the exterior cues and powertrain, ZR1 models will be distinguished from other Corvette models by their VIN. Each will carry a unique, identifying VIN digit, as well as a sequential build number. This makes it easy to determine the build number of a specific car - information treasured by enthusiasts and collectors. For example, a ZR1 with a VIN ending in "0150" would indicate it is the 150 th ZR1 built for the model year. __________________ Just the Facts: - This is the first time a prototype of the 2014 Chevrolet Corvette has been caught on camera.

- The final production version is expected to debut at the Detroit auto show in 2013.

- The Corvette will retain its traditional front-engine, rear-wheel-drive layout and feature a small-block V8.

KAPUSKASING, Ontario — Spy photographers have caught a glimpse of the 2014 Chevrolet Corvette undergoing cold-weather testing in Canada. It's the first time that the seventh-generation Corvette has been spotted in public. The heavily camouflaged prototype reveals a few minor details about the upcoming sports car. It will clearly retain the classic long-nose, short-deck configuration of its predecessors, but the profile of the car will feature a more distinct wedge shape. There are two different prototypes seen here, each with its own wheel design. Not sure if this is indicative of two different models or simply an easy way to try different tires in the snow. Shooters on the scene described an exhaust note that was most definitely of the V8 variety. Although our earlier Corvette Intelligence report suggested that a small-displacement turbocharged V8 might be used, the sound of this prototype was more in line with a more typical normally aspirated, large-displacement V8. Most speculation suggests that this Corvette with get a roughly 5.5-liter V8 that uses direct injection and variable valve timing to develop around 500 horsepower. Sources have told Inside Line that the C7 Corvette will also feature a seven-speed manual transmission. The official unveil of the 2014 Chevrolet Corvette is expected at the 2013 Detroit Auto Show early next year. Inside Line says: This is yet another chance for GM to show that it's serious about building world-beating cars. The Corvette has always had the performance; hopefully the C7 will have the refinement, too. Just the Facts: - The next-generation Corvette will offer a seven-speed manual transmission.

- Power will come from a pushrod V8; direct injection and a variable valve lift system are likely.

SANTA MONICA, California — Inside Line has learned that the 2014 C7 Chevrolet Corvette will be available with a seven-speed manual transmission. Although not confirmed officially by Chevrolet, a source with knowledge of the C7 project confirmed that the upcoming Corvette will offer a seven-speed manual transmission. This comes on the heels of Porsche's announcement that the 2012 911 would offer a seven-speed manual along with its seven-speed PDK dual-clutch automated manual gearbox. The next-generation Corvette is expected to use a revised version of its 16-valve pushrod V8 engine architecture. Headlining the changes are direct injection and a variable valve lift system to further enhance its already formidable performance while bolstering efficiency. The addition of a seven-speed manual might be viewed solely as a fuel efficiency play, but we suspect that Chevrolet will continue to use two overdrive gears like the current six-speed manual. This would allow the engineers freedom to tighten up the spacing of the lower gears for improved low-speed performance. Another benefit to the seven-speed manual gearbox is product rationalization — Chevy can use the same ratios for all versions of the car. Today, the ZR1 currently runs a close-ratio Tremec TR6060, while lesser Corvettes employ a different gearset. Inside Line says: The extra gear can't hurt, but we wouldn't mind a seven-speed dual-clutch like the one in the 911 as an option, too.

CHICAGO – The all-new, 2012 Chevrolet Camaro ZL1 is powered by the LSA 6.2L supercharged V-8 engine that produces an estimated 550 horsepower (410 kW) and 550 lb.-ft. of torque (745 Nm). The LSA is the most powerful engine ever offered in a Camaro, eclipsing even the original ZL1 engine from 1969 that inspired the name of the new, maximum-performance model. Built on GM’s legendary small-block V-8 architecture, it features an intercooled supercharger system, premium heat-resistant aluminum cylinder heads and other details designed to ensure its exceptional performance is delivered with smoothness and refinement. “The LSA is the ultimate engine for the ultimate Camaro,” said John Rydzewski, assistant chief engineer for small-block engines. “It has a broad power band that matches the Camaro ZL1’s performance capabilities at every notch on the tachometer.” Components and design elements that contribute to the LSA’s performance include: - Balanced, lightweight reciprocating assembly

- High-strength hypereutectic pistons

- Sixth-generation Eaton supercharger with four-lobe rotors

- Center-feed fuel system

- Piston oil squirters.

A Tremec TR6060 six-speed manual transmission is matched with the LSA. It uses a 240-mm dual-mass flywheel matched with a 240-mm twin-disc clutch system to provide excellent shift smoothness. Compared to the Cadillac application, the LSA used in the Camaro features the following unique components and details: - Black intercooler housing with unique heat exchanger and plumbing to accommodate the Camaro engine compartment

- Cast stainless steel exhaust manifolds for enhanced thermal management

- Camaro-specific oil pan

- Revised accessory drive with unique alternator and air conditioning compressor

- Idler pulley in place of the conventional power steering pump pulley, because of the use of electric power steering

- Special engine cover in red.

Supercharged power delivery

The LSA engine’s sixth-generation Eaton supercharger, with high-helix, four-lobe rotors, enables a broad range of power through the rpm band, giving the engine great low-end torque and excellent horsepower at higher rpm. “The design of the supercharger’s rotating internal components extends its effective range, giving the engine a wide, flat power band that is usable at all rpm levels,” said Rydzewski, assistant chief engineer. “Whether at low speeds or on the highway, the feeling of power is instant, strong and sustained.” Heavy-duty and lightweight reciprocating components support the engine’s high-rpm, supercharged performance. The parts are housed in an aluminum cylinder block that features nodular iron, six-bolt main caps. Cast iron cylinder liners – measuring 4.06 inches (103.25 mm) in bore diameter – are inserted in the aluminum block and they are finish-bored and honed with a deck plate installed. The deck plate simulates the pressure and minute dimensional variances applied to the block when the cylinder heads are installed, ensuring a higher degree of accuracy that promotes maximum cylinder head sealing, piston ring fit and overall engine performance. Nestled inside the LSA’s deep-skirted cylinder block is a forged steel crankshaft that delivers a 3.62-inch (92 mm) stroke. It features an eight-bolt flange – the outer face of the crankshaft on which the flywheel is mounted – that provides enhanced clamping strength. Other non-supercharged GM 6.2L engines have a six-bolt flange. A torsional damper mounted to the front of the crankshaft features a keyway and friction washer, which is designed to support the engine’s high loads. Connected to the crankshaft is a set of lightweight powder-metal connecting rods and hypereutectic pistons, which, when combined with the cylinder heads, delivers a 9.1:1 compression ratio. The alloy of the pistons was selected for its strength and heat resistance properties, while the cast design provides inherent quieting advantages over other piston materials, such as forged aluminum. Exceptional airflow

High-flow cylinder heads based on GM’s proven L92 design channel incoming air into the combustion chambers. They are made with a premium A356T6 alloy that offers excellent heat resistance, particularly in the bridge area of the cylinder head, between the intake and exhaust valves. Additionally, each head is manufactured with a roto-casting method. Also known as spin casting, the roto-casting process involves pouring the molten alloy into a rotating mold, for a more even distribution of the material that virtually eliminates porosity – air bubbles or pockets trapped in the casting – for a stronger finished product. For optimal combustion, the cylinder heads feature swirl-inducing wings cast into the intake ports, improving the mixture motion of the pressurized air/fuel charge. The gatekeepers of the heads’ combustion chambers are large-diameter, 2.16-inch (55 mm) intake valves and 1.59-inch (40.4 mm) exhaust valves. The intake valves are made of steel and feature thick heads. Unique, four-layer steel head gaskets are used between the heads and cylinder block. The LSA’s valves are actuated by a hydraulic roller-type camshaft that delivers a relatively low 0.480-inch (12.2 mm) lift on both the intake and exhaust sides. The low lift – relative to the engine’s high horsepower and torque – and low overlap foster a smoother idle and excellent low-rpm driving characteristics. The wider efficiency band of the Eaton supercharger enabled the use of the low-lift cam to achieve the engine’s performance targets. Sixth-generation supercharger

The LSA’s supercharger is the sixth-generation design from Eaton and displaces 1.9 liters. It features a four-lobe rotor design that promotes quieter and more efficient performance, while its large displacement ensures adequate air volume at high rpm. Maximum boost is 9.0 psi (0.62 bar). The supercharger is an engine-driven air pump that contains a pair of long rotors that are twisted somewhat like pretzel sticks. As they spin, the lobes mesh and incoming air is squeezed between the rotors and pushed under pressure into the engine – forcing more air into the engine that it could draw under natural aspiration. The rotors are driven by a dedicated pulley and eight-rib belt that are connected to a third track on the engine’s crankshaft damper. Because the pressurized air is hotter than naturally aspirated air, the LSA employs a liquid-to-air charge cooling system to reduce inlet air temperature after it exits the supercharger – reducing the inlet air temperature by up to 70 degrees C (158 degrees F). Cooler air is denser and allows the engine to make the most of its high-pressure air charge. The charge cooler’s heat exchanger is located atop the supercharger. This “brick,” as it is called by engineers, looks like a small radiator and is housed under an aluminum cover. Pressurized air from the supercharger passes through the exchanger and is cooled on its way to the cylinder heads. The charge cooling system includes a dedicated coolant circuit with a remote-mounted pump and reservoir. Ribs cast into the top of the intercooler housing add strength and promote quietness. Quiet fuel system and more

The LSA uses a center-feed fuel system that contributes to the engine’s performance and refinement. It introduces fuel at the midpoint of each cylinder bank’s fuel rail, which ensures more even fuel delivery to all the injectors. It also isolates fuel system noise for quieter performance. Several other features support the LSA’s balance of refinement and power, including: - An oil pan-mounted oil cooler to manage engine oil temperature

- Block-mounted piston squirters to cool the pistons

- Direct-mounted ignition coils (located on the rocker covers)

- A large, 87mm electronically controlled throttle body.

The engine also has unique, cast stainless exhaust manifolds that support the airflow capability of the 550-horsepower (410 kW) engine.

Lingenfelter Performance Engineering

Callaway Cars

Hennessey Performance Engineering

Super Yenko Chevrolets

Trans Am Depot

|